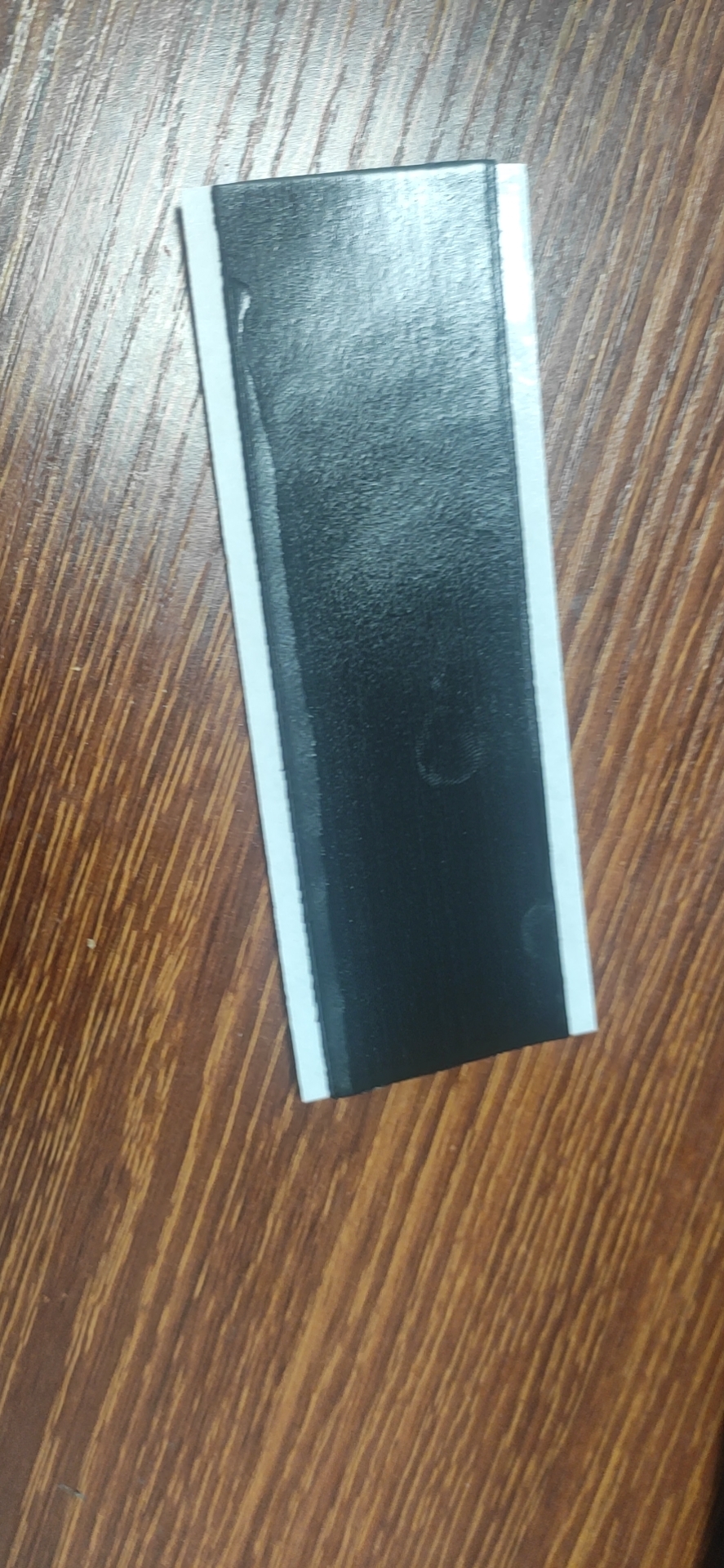

Butyl Tape

Technical Data

Chemical Base: Butyl rubber compound

Adhesion: 20lbs.+/in width

Density: 1.4 g/cm3±0.5g(Per 1mm thickness)

Application Temperature: 0℃~40℃

Fire Rating: E (EN 11925-2; EN 13501-1)

Service Temperature: -30°C to +90°C

Tensile Strength:

Longitudinally: ≥150 N/50 mm (EN 12311-1)

Transversely: ≥150 N/50 mm (EN 12311-1)

Elongation at Break: ≥ 20 % (EN 12311-1)

Pliability: No cracks in membrane

Peel adhesion @ 90 °:

≥ 70 N (ASTM D 1000)

*All technical data stated in this Product Data Sheet are based on laboratory tests. Actual measured data may

vary due to circumstances beyond our control.

Application Range

● Roofs - around chimneys and skylights, over joints/ cracks in tiles and roof cladding.

● Exterior walls - joints and cracks in asbestos cement sheeting, cracks under masonry ties and anchorages, around wall penetrations (such as water pipes), gutters and down pipes.

● Terraces - at joints between terraces and exterior walls, joints in parapets, roof edges, sides, flashing and joints.

● Car industry, repairing of roof and cars.RGT-BS Butyl Rubber Strip-March 2019 3rd

Adhesion

Steel, aluminium, metals, concrete, stone, bricks, cement plaster, polycarbonate, PVC, TPO,glass, and wood.

Storage stability

12 months from date of production if stored in unopened, undamaged original sealed containers, in dry conditions and protected form direct sunlight at temperatures between +5°Cand +40°C.

Installing Guideline

● The surfaces to be sealed must be dry, capable of bearing load and free from grease and dust.Remove all loose dust and dirt with a wire brush and soft broom from the area of application.

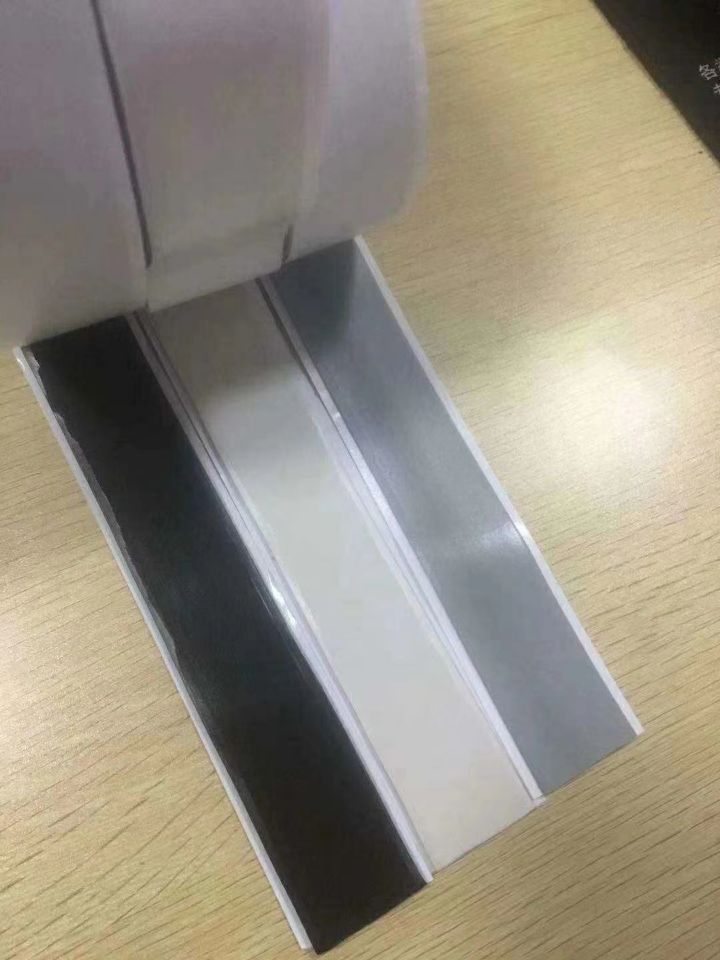

● Unroll and cut butyl stripe to the required length.

● Peel the backing strip and apply the adhesive side onto the prepared substrate.

● Smooth down using a roller or gentle fingertip pressure to prevent air pockets and creases, and to ensure a good tight seal.It is very important to press down the edges and ends of the tape.All joint connections have to be overlapped.

Attention

1) Before use , remove water ,oil dust and other dirt from the surface.

2) The strip should be kept in a cool dry place , away from heat , sun or rain.

3) The product belongs to the self-adhesive material , one time paste can achieve the best waterproof effect .

4)At temperatures below +5 ° C the tape and the substrate must be warmed before and during the application. Use hot air equipment.RGT-BS Butyl Rubber Strip-March 2019 4th

Limit

1) Not suitable for sealing against water pressure.

2) Butyl adhesives are sensitive to solvents. Check chemical compatibility of the butyl adhesive with the substrate.

3) Do not use for permanent fixing or in load bearing applications instead of an