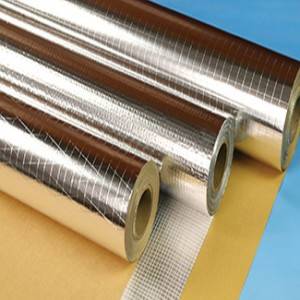

Self Wound Aluminum Foil Tape

I. Features

High tensile strength, easy for to operate, no waste and environment-friendly; easy for site bonding, with improved bonding efficiency, suitable for machine bonding.

II. Application

Suitable for fixation of radiator fin in refrigerators and freezers, and elimination and shielding of electromagnetic wave interference of various electronic products.

III. Tape Performance

| Product Code | Foil Thickness(mm) | Adhesive | Initial Tack(mm)> | Peel Strength (N/25mm)> | Holding Power>(h) | Temperature Resistance>(℃) | Operation Temperature(℃) | Features |

| T-F**03WL | 0.03-0.075 | Emulsion acrylic adhesive | ≤100 | ≥15 | ≥5 | -20~+60 | +10~+40 | Pure aluminum base material, with good initial tack and low temperature resistance; environment-friendly. |

| T-F**04WL | 0.03-0.075 | Solvent-based acrylic adhesive | ≤200 | ≥18 | ≥24 | -20~+120 | +10~+40 | Pure aluminum base material, with good tack and high temperature resistance, and good water resistance. |

| T-F**05WL | 0.03-0.075 | Solvent-based>cold weather>>acrylic adhesive>>> | ≤50 | ≥15 | ≥24 | -40~+120 | -5~+40 | Pure aluminum base material, with good weather resistance and low temperature resistance; maintaining excellent initial tack and adhesion under low temperature. |

| T-PF**04WL | 0.035-0.085 | Solvent-based acrylic adhesive | ≤200 | ≥18 | ≥24 | -20~+120 | +10~+40 | PET composite aluminum foil base material, can and eliminate and shield electromagnetic wave interference. |

Note:1. Information and data are for universal values of product testing, and do not represent the actual value of each product.

2. Tape in parent roll has a width of 1200mm, and small volume width and length can be customized according to customer request.